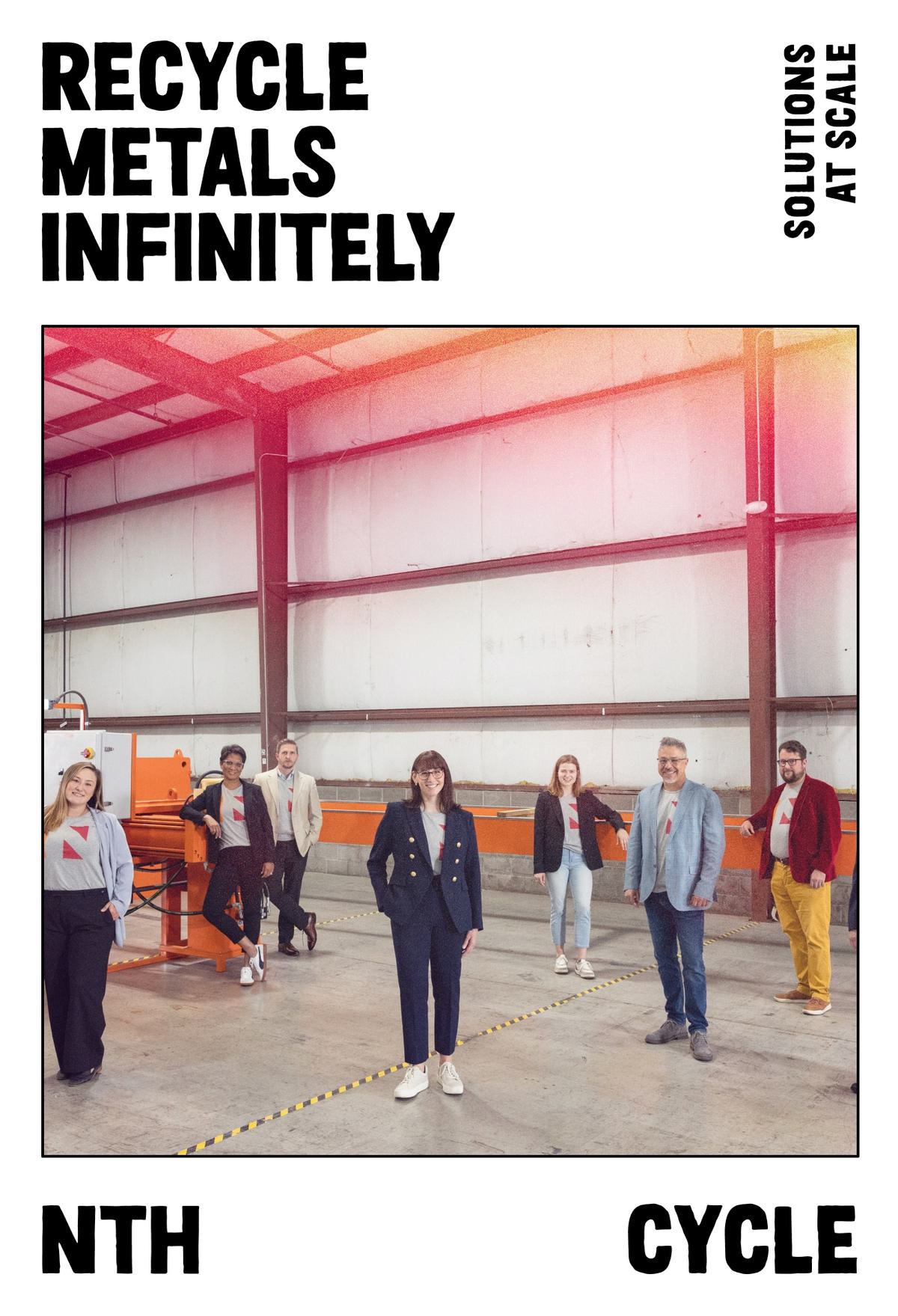

Nth Cycle

Nth Cycle is a metal refining technology company dedicated to providing a clean, safe alternative to overseas smelting. Their mission is to keep critical metals in circulation forever. To meet the demands of a rapidly decarbonizing society, the U.S. needs a dramatically scaled supply of critical metals like cobalt and nickel. Nth Cycle’s patented modular refining system, The Oyster, extracts high-purity metals using just electricity and water.

Nth Cycle is revolutionizing metal refining to create a sustainable metals supply chain.

Society is at a crossroad as it tries to build a carbon-free world. The very technologies designed to save us — electric vehicles, wind turbines, and processing power — are built on a foundation of metals extracted from the earth at great monetary and environmental cost. How can the world shift to a carbon-free existence without doing more harm than good?

Nth Cycle sees this challenge as an opportunity to draw the resources needed for the energy transition from electronics waste, scrap yards, and more efficient mines, and make recovery processes more sustainable while also improving profits. The tools required to mine cobalt, nickel, copper, and manganese exist today. The technologies needed to break down old cell phones, magnets, circuit boards, and electric vehicles into their component parts exists today. But, the incumbent processes that transform these harvests into production-grade critical minerals for new manufacturing are inefficient, carbon-intensive, and expensive.

-

Nth Cycle’s GHG potential in mining is about 92% lower than laterite mining’s, and 76% lower than sulphide mining’s.

-

Nth Cycle’s recycling process is about 44% lower GHG in emissions than current processes.

-

Nth Cycle can process any type of metal-bearing feedstock (ore, scrap, tailings) with +90% metal recovery.

-

The Oyster refining system has a footprint of less than 2,000 sq ft which enables on-site refining and no transportation of hazardous or low-grade materials.

-

-

Alberto

Commercial Manager

-

Why This Matters

In transforming our lives and economies, the technologies used must be as clean and sustainable as the world imagined. Metals are needed for everything in our electrified world — from cell phones to EV cars.

-

What You Can Do

Do you know how a cell phone or EV battery is made? It should use recycled metals, made from the cleanest refining technology, not toxic chemicals or burning at a high heat. Learn how they plan to recycle metals infinitely at NthCycle.com